PROJECTS

-

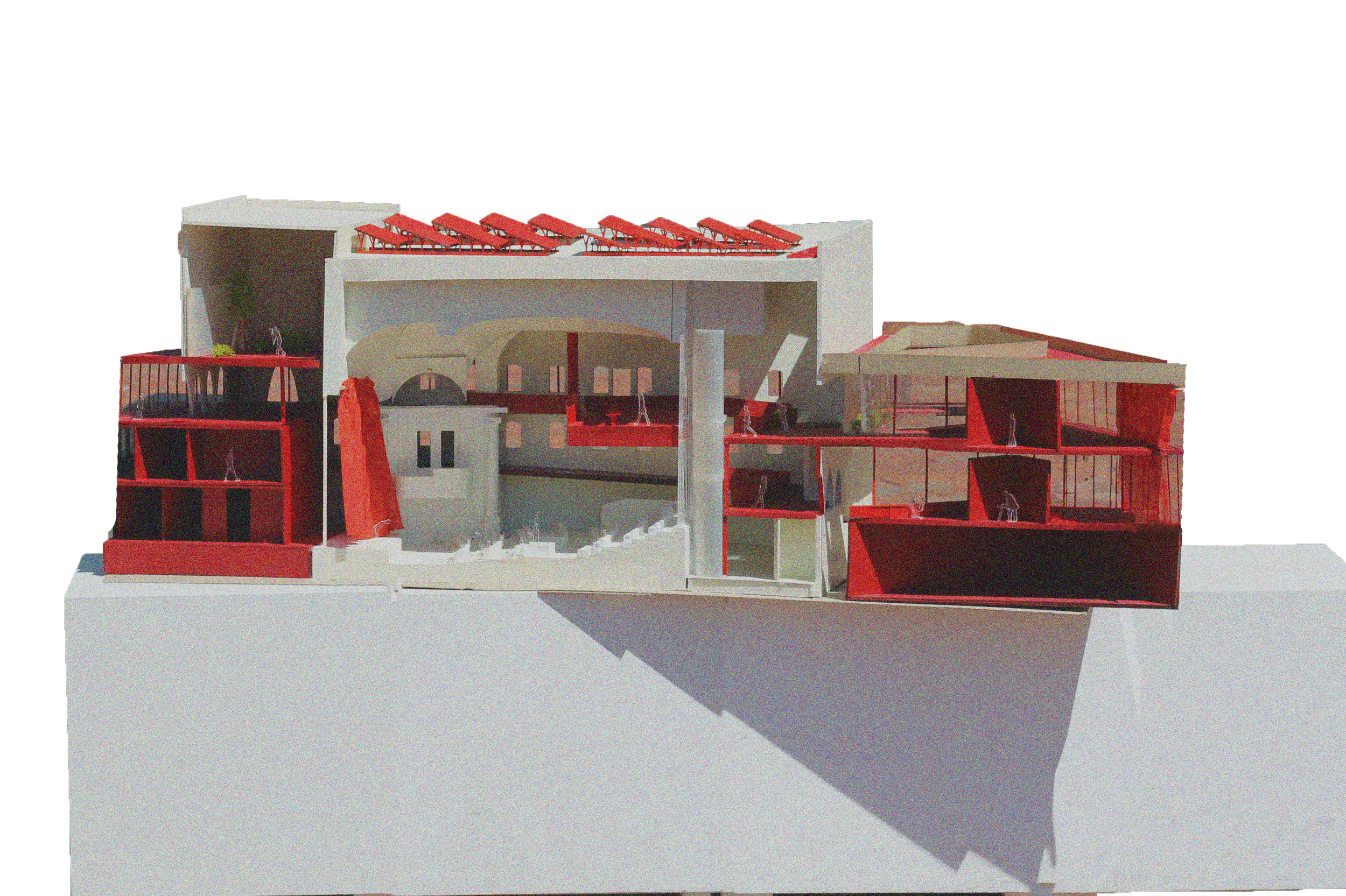

1/4” scale model of an adaptive reuse project

-

SUBMISSION OF HOBSON AWARD FOR BSA

-

Fabrication of various models that were made during my co-op at Sasaki

-

First fabrication project that was made during my first co-op.

COMPREHENSIVE STUDIO

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more or maybe you have a creative project.

HOBSON AWARD

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more or maybe you have a creative project.

SASAKI FABRICATION

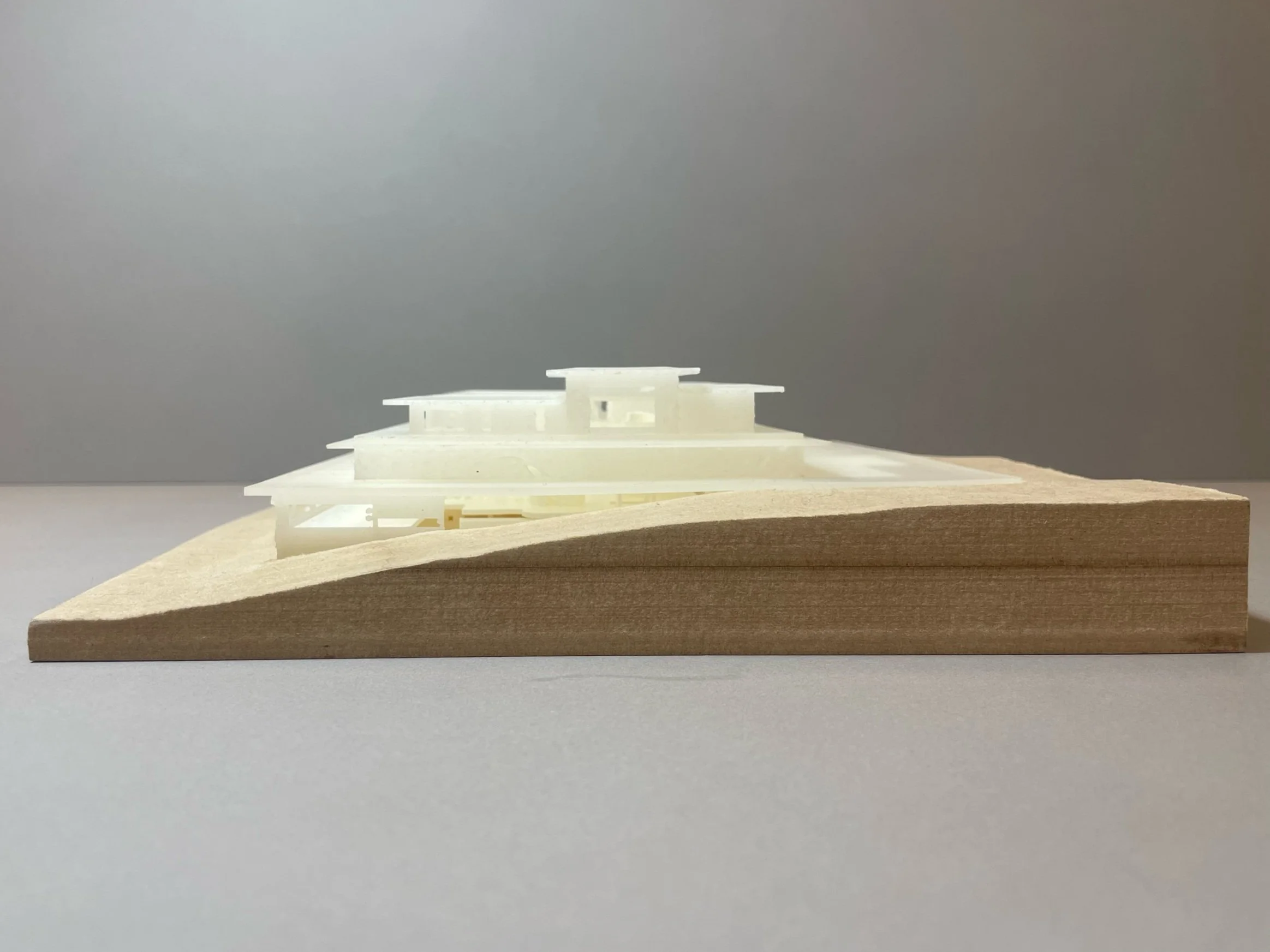

UC BERKELEY ADA TRANSITION

The scope of this project was to reimagine the accessibility aspect of the UC Berkeley campus in California. One way of studying the campus topography was to create physical models. In addition, during the creation process, Sasaki teamed up with Chris Downey, principal at Architecture for the Blind, and the model started serving a different purpose.

The CNC and milled model was able to represent the accessibility concerns by tracing it with hands. Following that ideology, Sasaki produced a stepped topography milling system that would allow the model to be easily navigated with touch.

AMHERST COLLEGE SCALED MODEL

During my 6 month coop at the Sasaki Fabrication studio, I was responsible for fabricating various models for the existing design using industry-grade machinery.

The Amherst College models were an exploration of materiality and the discovery of various modeling techniques. The project was in collaboration with Herzog de Meuron and partners from Amherst College.

I was required to create a 10x10-inch model that would represent the difference between the old structure and the newly constructed exterior of the new Student Center Dining Commons.

Challenges included understanding the principles behind 3D printing and achieving the level of opacity that would allow the interior structure to be exposed. My responsibilities included conducting optimized 3D modeling techniques. This involved understanding different printing techniques and producing Rhino files. Additionally, I conducted CNC milling for the MDF base and trials with different materials.

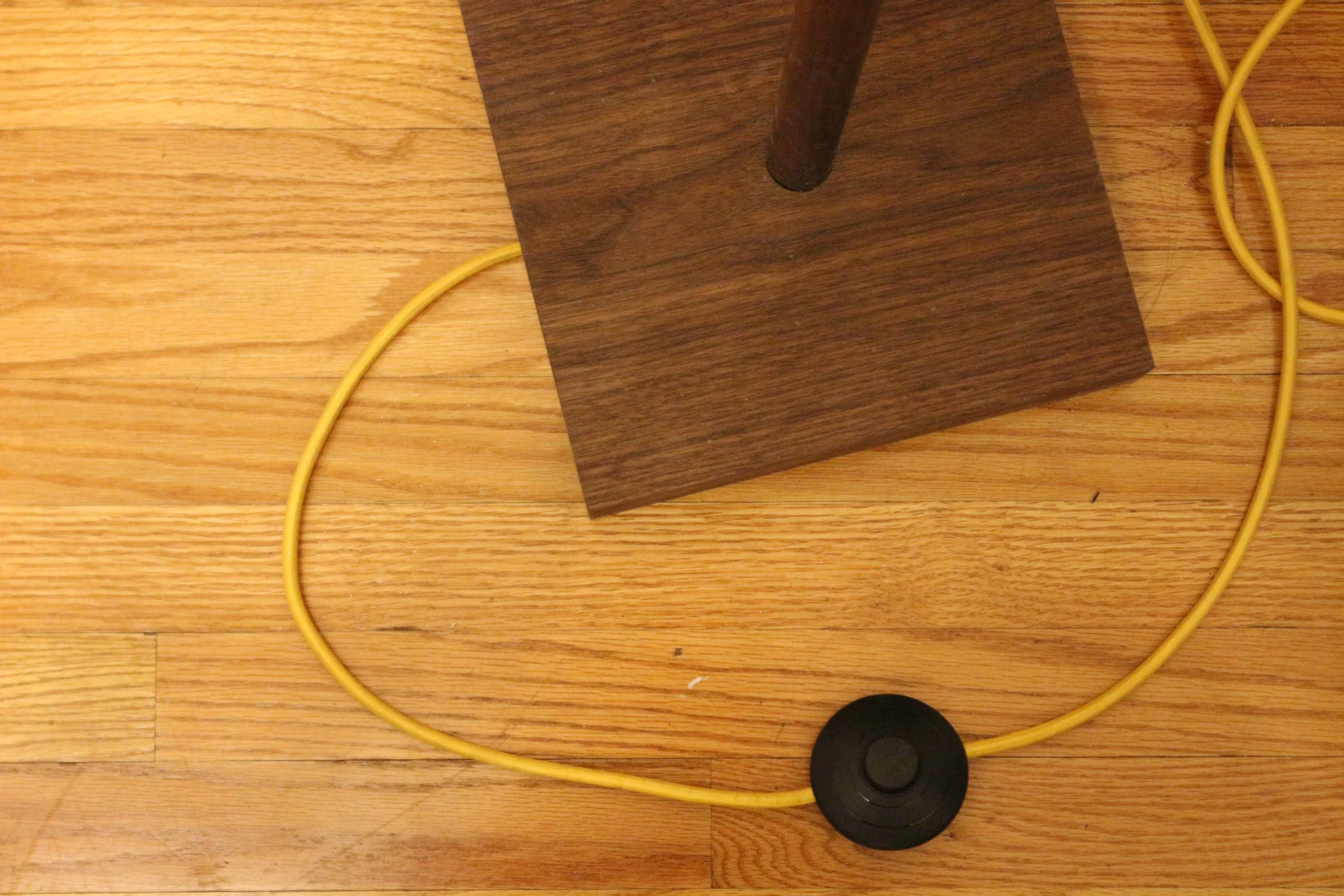

The Lamp Project.

Fall 2021

The main part of the lamp design was to understand systematic connections between each component. The most challenging part was creating a system between the triangles and integrating it with an original socket design. On the left, you can see the initial sketch and triangle ideas. Moving on from that, I built it up based on material availability.